Custom Design Improves Fabrication Processes

“Eliminating unnecessary steps whenever possible without decreasing quality. All the while, every team member worked to improve their knowledge and efficiency of every step.” MSM Equipment is serving customers needing custom equipment with improved manufacturing processes and innovative manufacturing equipment.

“Our reputation in stainless steel fabrication is well-earned over our long history of innovation and safety,” said Sherry Wong, Production Manager of MSM Equipment, “Serving custom made equipment was a challenge and innovative step for us and now we’ve invested in the equipment and processes to do so.”

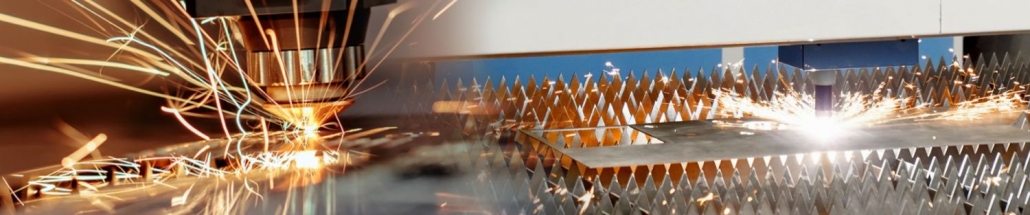

MSM Equipment recently streamlined manufacturing processes and added innovative equipment to ensure quality and safety. The team now uses laser cutting system to trim different thickness of plate sections to size. The MSM team is working to improve efficiency production with their laser machine that pushes 1.7G acceleration.

It is an incredibly fast, accurate, fully enclosed laser machine, opens a new era of laser cutting performance for commercial and industrial applications. World record, quality picture marking on that big format lasers. “We purchased this equipment to enable us to provide more competitive pricing for better deliveries and improved operational efficiency.”

2. Custom Design Shelving with Hanger

3. OT Control Panel for Hospital

4. Grossing Unit for Lab Equipment

For medium and heavy bending tasks, we have two units bending machine with AC servo motor, high speed ball screw and linear guide way. The machine is solid welded construction featuring all rollers mated with high-quality, heavy-duty ball bearings, which ensures minimum friction and even rotation of the bending rollers.

These state-of-the-art hydraulic benders with top brand components to ensure high-quality lifelong performance. “They are easy to operate and we are continuing to learn through the process,” Sherry Wong tells us, “the inputs are easy to make and the machine operates with ease.”

During the fabrication re-set, team members at MSM leveraged learning gained over years of innovation in stainless steel fabrication areas to refine processes, eliminating unnecessary steps whenever possible without decreasing quality. “This team’s work ethic and immense pride in what they produce is palpable. You know you have a MSM product when you take delivery of your custom product.” said Sherry Wong. Now we are delivering to MSM customers faster and more efficiently.